2021-10-13 10:42:50 Editor:ym

Kaifu Technology's blockbuster product Y2SS3-EC closed-loop bus stepper driver, the product perfectly integrates closed-loop control technology in the stepper motor, and greatly expands the function of EtherCAT, with a new excellent performance and a wide range of applications. Y2SS3-EC is a high-performance bus-controlled closed-loop stepper motor driver. The driver has built-in EtherCAT communication protocol, which can be used as a standard EtherCAT slave station, supported by CANopen over EtherCAT(CoE). At the same time, it can also be used with a variety of closed-loop stepper motors of different sizes.

EtherCAT® is a registered trademark and patented technology licensed by Beckhoff Automation GMBH.

The Y2SS3-EC two-port RJ-45 connector is a 100BASE-TX(100Mbps) compliant interface that can be connected using standard network cables. Use CAT5 or CAT5e(or higher) network cables. The Ethernet input interface IN is connected to the Ethernet output interface OUT of the previous drive on the controller or bus. The Ethernet output interface OUT is connected to the Ethernet input interface IN of the next drive on the bus. If the drive is the last node on the bus, just connect the Ethernet input interface IN. No need to use a terminal matching resistor.

Y2SS3-EC supports synchronous mode and non-synchronous mode EtherCAT control mode. In synchronous motion mode, the master station plans the trajectory and outputs the periodic command, and the driver receives the planning command of the master station according to the synchronous cycle, which is suitable for multi-axis synchronous motion. The Y2SS3-EC synchronous motion mode supports cyclic synchronous position mode (CSP). In cyclic synchronous position mode (CSP), the trajectory planning is completed at the master station, the position information sent by the master station is received according to the synchronization period, and the position information is immediately transmitted to the driver when the synchronization signal arrives. The synchronization period supported by Y2SS3-EC is as follows: 1000 us, 2000 us, 4000 us.

1. Technical specifications:

输入电源电压 | 24~48VDC |

输出电流 | 0.1~7A(峰值) |

匹配电机 | 20~86 闭环步进电机 |

数字输入信号 | 光电隔离,差分,5~24VDC 高电平逻辑 原点信号,正向限位,负向限位,急停,探针 |

数字输出信号 | 光电隔离,集电极开路,最大 24V/100mA 抱闸输出,报警输出,到位输出 |

编码器输入信号 | 5V 差分,增量式编码器A/B/Z 相信号 |

通信接口 | EtherCAT(RJ45 连接器)和 Type-C(用于配置) |

支持协议 | CoE (CiA 402 协议) |

运行模式 | Profifile Position, Profifile Velocity, Cyclic Synchronous Position, Cyclic Synchronous Velocity ,Homing 模式 |

电气保护 | 过压保护,欠压保护,过温保护,过流保护,电机线开路检测,电 机过载检测等 |

状态指示 | 1 个红灯和 1 个绿灯 |

质量 | 0.293Kg |

二、电源的选择:

驱动器电源电压在规定范围之间都可以正常工作,如果您需要电机获得更好的高速性能,则需要提高驱动器供电电压。

供电电源电流一般根据驱动器的输出相电流来确定。通常情况下,驱动器电源电流可取驱动器输出电流的1.1~1.3倍。

同时,电源输入电流的大小还与电机运行时转速及负载有关,因此对于具体的应用场合,用户还需进行特定的分析和估算。

三、电机的选配:

Y2SS3-EC最大可输出7A电流,可适配86及86以下法兰尺寸的两相直流步进电机。

Y2SS3-EC具备开闭环一体特性,开环或者闭环的步进电机均可兼容。

步进电机选型须根据相关机构负载来计算确认,可联系凯福科技公司热线(400-960-1069)咨询电机选型的具体办法!

四、使用环境:

使用场合 | 避免粉尘,油雾腐蚀性气体,湿度太大及强振动场所,禁止 有可燃气体和导电灰尘,自然冷却或强制风冷; |

环境温度 | 0~50℃ |

环境湿度 | 40~90%RH |

振动 | 10~55Hz/0.15m |

保存温度 | -20℃~65℃ |

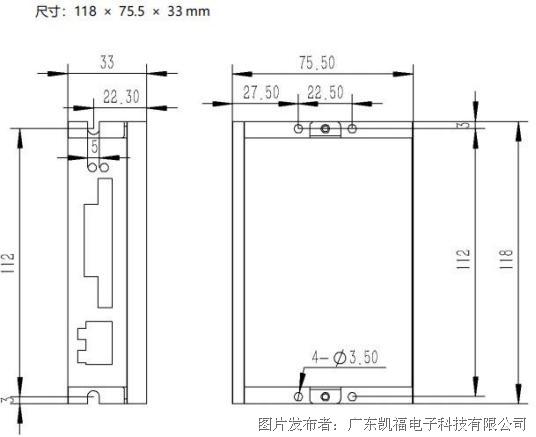

五、机械尺寸:

* 推荐采用竖着侧面安装,使散热齿形成较强的空气对流:必要时机内靠近驱动器处装风扇,强制散热,保证驱动器在可靠工作温度范围内工作。

六、驱动器连接说明:

为了更好的满足市场需求,凯福科技隆重推出新款总线型驱动器 Y2SS3-EC,相比老款EEDC和EEDO系列以及市面上的总线驱动器,新款Y2SS3-EC 总结具有以下特点,欢迎新老客户来电咨询,获取样品,来电咨询!

一、 性能优越:

① 由于采用先进的高端伺服同步技术,在2ms的环路周期,轻松实现100多轴同步控制;

② 减少马达发热Y2SS3-EC闭环采用建模等效技术,实现步进模式下电流幅值自动调整,减少发热,同时能够实现位置环 高速快速响应,保持原开环步进驱动器的刚性。

③ 提升马达力矩、提升控制响应时间Y2SS3-EC相同电流情况下,马达力矩普遍提升5%-10%,控制响应时间提升30%,在额定负载范围内,几乎可以实现一个码盘脉冲控制精度。

二、 适配能力强:

① 内置虚拟按键选择电机参数,选择完成后几乎不用调节参数就能运行,参数调节简单。

② Y2SS3-EC研究出高端伺服拥有的控制环路与ECAT高精度时钟实时同步调整技术,几乎可以适配市面所有的控制器,内置插补时间自动探测与调整,几乎不需要人为调节就可以并机运行。

三、 高性价比:

① 减少物料:Y2SS3-EC开闭环兼容,可以搭配20mm-86mm系列步进电机,实现了让客户使用总线型步进电机只需要一款驱动器的愿望。