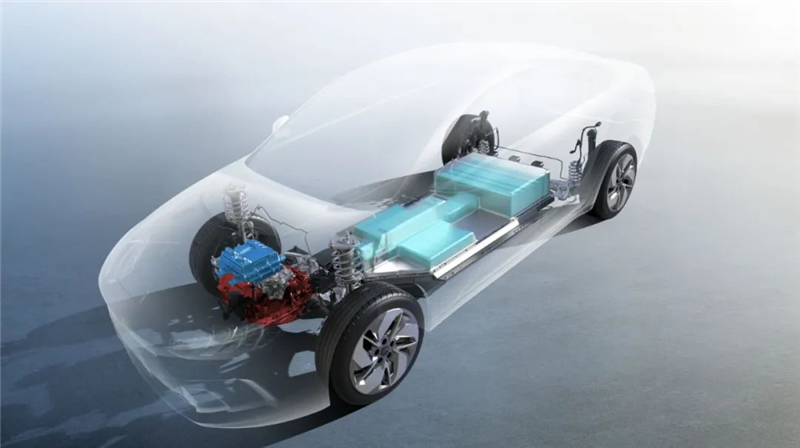

The direct role of the power battery is to provide power source for electric vehicles. Many electric vehicle power batteries use ternary lithium batteries, which use compounds such as lithium manganate or lithium nickelate as positive electrodes, and use organic electrolytes with carbon materials that can be embedded in lithium ions as negative electrodes

According to the Lithium Battery Research Institute (GGII), the installed capacity of soft pack batteries in China from January to October 2019 was about 3.99GWh, down 10% year-on-year, accounting for only 8.6% of the total installed capacity (13.4% of the total installed capacity last year). Square battery, installed capacity of about 39.12GWh, an increase of 49%, accounting for 84.35% of the total installed capacity.

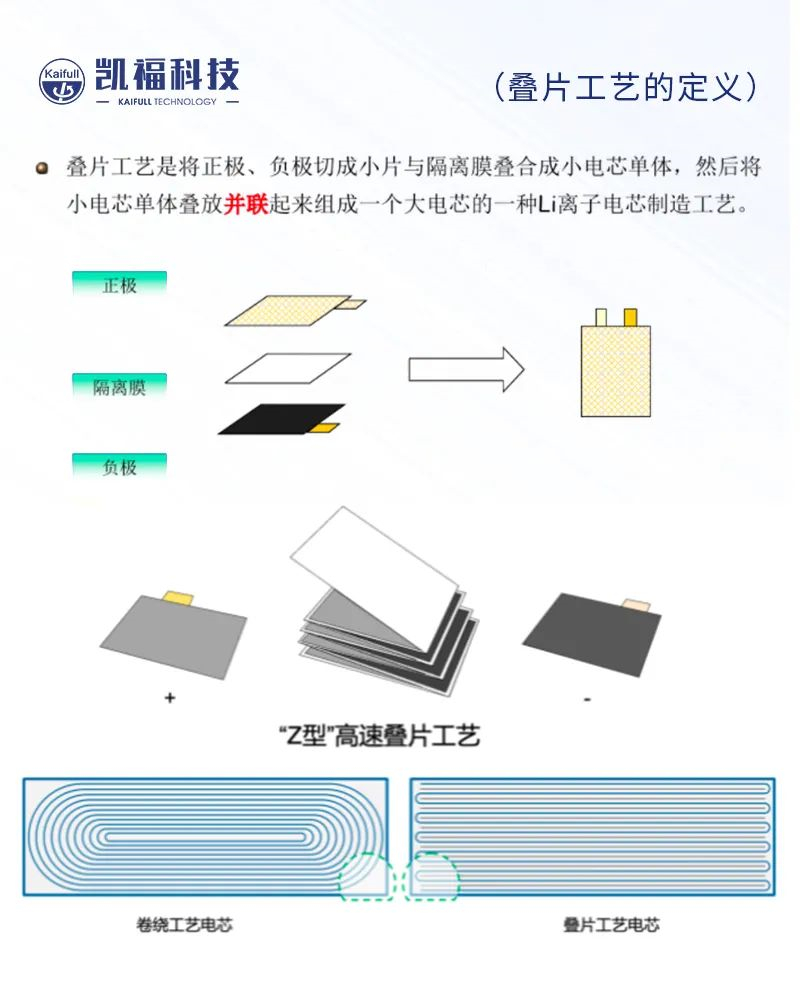

There are many reasons behind this, one of which is that the concentration and maturity of the "mainstream" laminating equipment are not enough, and the problems such as cell yield, excellent rate, equipment stability, and operation rate of the laminating process cannot be accurately solved during research and development.

However, the cells manufactured by the lamination process have the advantages of high energy density, small internal resistance, good discharge platform, easy to fast charge and release large current, and no dead Angle. In addition, in the era of all safety-oriented batteries, quality is the first important. Laminated devices still hold great promise.

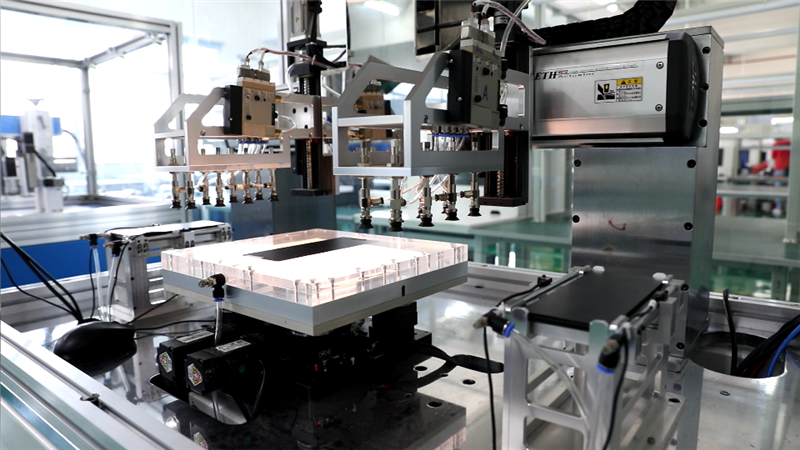

Kaifu has been committed to high-quality motion control products, and launched a software and hardware integration solution of "control + vision + drive + motor + alignment platform" for lithium-ion high-speed lamination equipment. It greatly improves the production efficiency and product quality of the laminator.

凯福对位平台锂电叠片方案

01

运动控制方案

Solution advantage: Strong performance. High precision, μ-level accurate positioning, EtherCAT network bus control, high-speed response. Vision, control, alignment integrated architecture design, more convenient application.

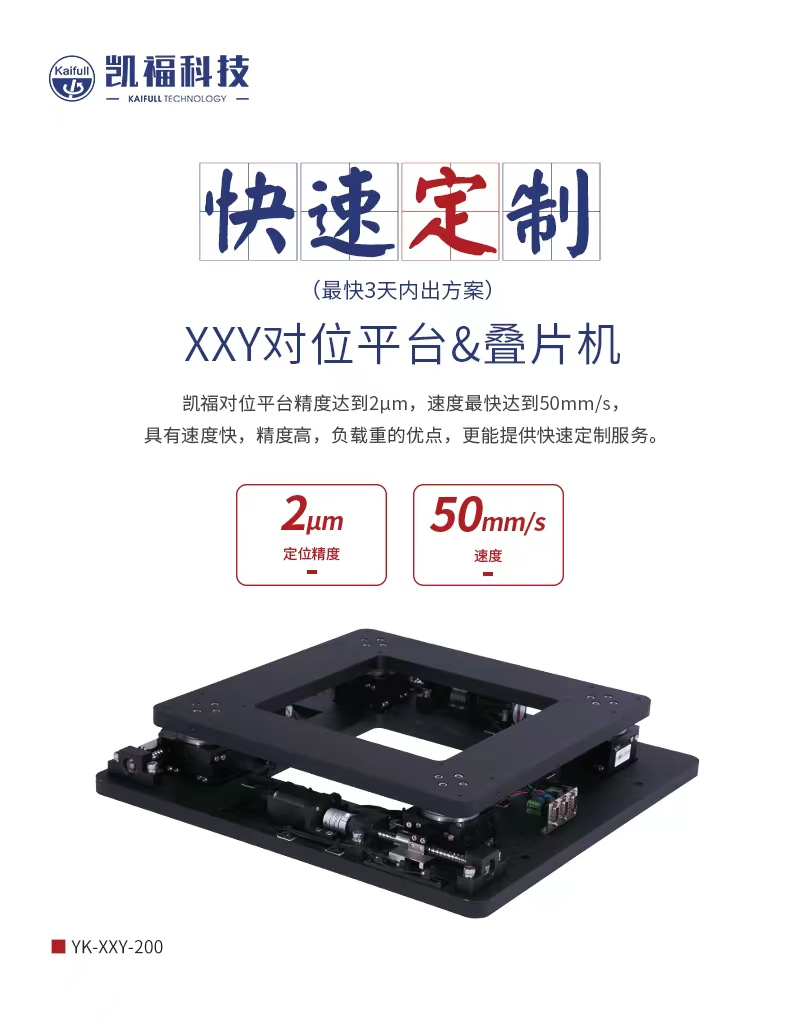

The "Precision alignment platform system" developed by Kaifull Technology integrates motion control and vision system solutions, and has a wide range of applications in lithium battery equipment, semiconductor equipment, optical fiber communication 5G equipment and other fields, greatly improving the accuracy and production efficiency of products, and providing efficient, comprehensive and reliable technology and services for customers' factories to achieve industrial automation.

If you have selection or technology-related problems, welcome to inquire, we will be happy to provide you with professional and rich technical solutions.