2020-10-21 11:35:50 Editor:凯福

Jitter is a common phenomenon during stepper motor rotation, but it is not inevitable.

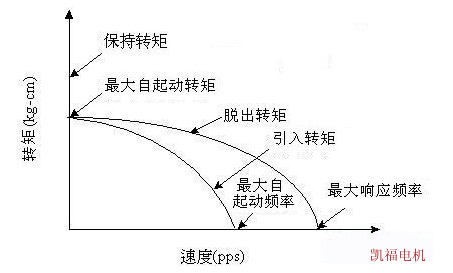

Before solving the problem, let's first familiarize ourselves with the principle and understand the vibration area of the stepper motor. After the input drive pulse, the stepper motor will vibrate when it rotates, when the natural vibration frequency of the rotor is consistent with the drive frequency, resonance phenomenon will occur, if the vibration becomes larger, the motor will be out of step and stop, or even wrong step or reverse phenomenon, the resonance frequency of the stepper motor is usually around 100~200H.

Stepper motor has a fixed resonance region, two, four phase induction type stepper motor resonance region is generally between 180-250 PPS (step Angle 1.8 degrees) or about 400pps (step Angle 0.9 degrees), the higher the motor drive voltage, the greater the motor current, the lighter the load, the smaller the motor volume, then the resonance region upward offset, vice versa, In order to make the output moment of the motor large, without losing step and reduce the noise of the whole system, the general operating point should be offset from the resonance region.

When you encounter the stepper motor jitter at startup and not running, jitter during operation, jitter at low speed and other conditions, according to the work experience of our engineers over the years, the first thing is that the stepper motor is small, other reasons and the solution to the stepper motor jitter are as follows:

1, the motor selection is small, the inertia is not enough, the solution is to replace the corresponding model of the motor

2, the current set is small, set the current to the corresponding value

3, the knob is not adjusted, adjust the knob to the corresponding gear

4, in the resonance area, it is recommended to adjust the subdivision or bypass this area

5, the motor wiring error (mainly 8-lead motor), the motor lead connection