2020-02-21 10:12:17 Editor:小编

Generally, the stepper motor is used in 3D printers, which is a very important power component of 3D printers, and its stability and operating accuracy directly affect the quality of 3D printers. As a discrete motion device, it is different from the ordinary AC and DC motor, the ordinary motor turns when it gives electricity, but the stepper motor is not, it is to perform a step on receiving a command. The main reason for not choosing servo is that the accuracy of the stepper motor meets the requirements and the cost is much lower than it, and now more engineers are inclined to absolute encoder motors.

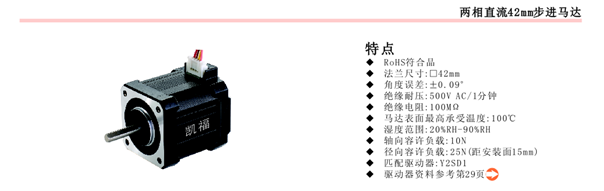

In 3D printers, most of the use of 42 stepper motor, the selection usually need to consider the current, shaft diameter, heat, motor drive and other parameters, for desktop level 3D printer is enough to choose 42 stepper motor, if there is no special requirements, 1.5A current can be. Most of the stepper motors of 3D printers are driven by synchronous belts, which require synchronous wheels and couplings, so the diameter of the selected motor shaft is generally about 5mm. Motor heating is a problem that needs to be paid attention to, which is related to the original design of the equipment, so in the initial stage of design to consider the electrical current input and output, a good motor internal coil can withstand the temperature of up to 130 ° C, the motor surface temperature can be maintained at 100 ° C at the same time to maintain normal operation. The motor driver is used with the stepper motor, its quality directly affects its own heat dissipation function, the use of electronic components and patch mode is also doomed to its functionality and service life, and the flange 42mm stepper motor supporting the use of pulse motor driver.

In the selection of 3D printer stepper motor, if you can not accurately grasp, you can call for advice! The characteristics of the 3d printer stepper motor produced and sold by the company are as follows: